About the Project

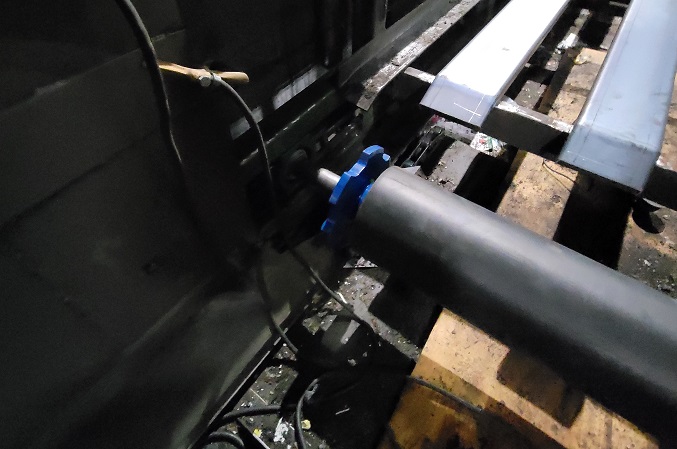

A chain edge crossover belt conveyor had worn down and the customer elected to perform selective maintenance in order to avoid an emergency breakdown.

- Recycling plant

- Custom-built, aging conveyor with 72’ x 72” belt

- Worn belt and supporting components

- Turn-key service needed, from scoping to parts ordering, custom fabrication, belt and part preparation, and final rebuild on-site.

The Problem

A critical chain edge conveyor was wearing and near failure. The customer proactively seeking a partner to perform a rebuild of the conveyor.

- Aging components, including the conveyor belt

- Little to no documentation on the conveyor

- Conveyor downtime = lost profits for customer

- Little flexibility on the calendar to schedule repair/rebuilt work

The Solution

Lovegreen team provided turn-key services to act as the sole partner on this project. Project management developed a plan, timeline, and work scope that delivered a full rebuild over two days.

- Field verification of all parts and components.

- Developed parts list and sourced all stock parts, including chain, belt, sprockets, shafts, and bearings.

Fabricated non-stock parts including chain guides, flights, and impact pans. - Accommodate customer’s need for a weekend-only, two-day timeline for the on-site rebuild portion of the project, starting Friday night and finishing Sunday morning.

- Field team of four (4) millwrights on days and four (4) on nights, all working 12-hour shifts.

- Customer expectations were met and the conveyor was immediately operational following the rebuild.

- Specialized equipment used:

- Forklift – 15,000 lb

- Forklift – 19,000 lb

- Chain Falls – 1 & 2 ton

- Suitcase welders