About the Project

A glass manufacturer brought in Lovegreen millwrights to supplement its internal maintenance team and address several longstanding issues on critical production lines. Tasks ranged from testing pneumatic controls to field welding and full equipment demolition.

Scope of Work Included:

- Testing and installing pneumatic controls on pallet conveyance lines

- Eliminating material spillage from conveyance sections

- Demolition of two inactive production lines

- Spot maintenance and equipment adjustments

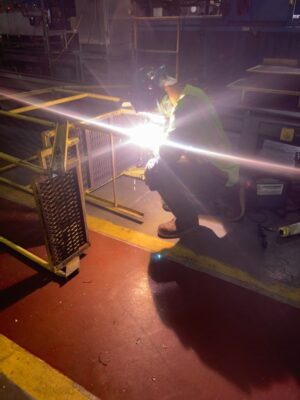

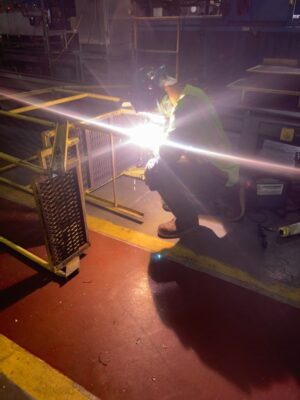

- Onsite field welding and rigging without forklift access

The Problem

After losing key maintenance personnel to retirement, the manufacturer faced a growing list of unresolved issues. Newer staff lacked the experience to tackle complex repairs, resulting in production inefficiencies and safety concerns:

- Pallets rolling off conveyance lines

- Frequent material spillage creating slip hazards

- Inactive equipment cluttering floor space and limiting production layout flexibility

The Solution

Lovegreen deployed a millwright crew to support the customer’s existing maintenance staff. Initially scoped for two days, the engagement expanded into a multi-week effort based on value delivered.

Key tasks included:

- Installing pneumatic pallet stops to prevent roll-off

- Adding 4″ sheet steel to conveyance systems to contain material flow

- Re-aligning sensors and photo eyes for consistent automation feedback

- Torch-cutting and rigging out obsolete lines from beneath active conveyors—without forklift access

- Scaling labor from 2 to 4+ millwrights over the course of 4 weeks