About the Project

A recycling facility proactively partnered with Lovegreen to rebuild a custom 72’ chain edge crossover belt conveyor nearing failure. The customer needed full-service support, from site verification and part sourcing to fabrication and final installation, to avoid unplanned downtime.

- Facility: Recycling plant

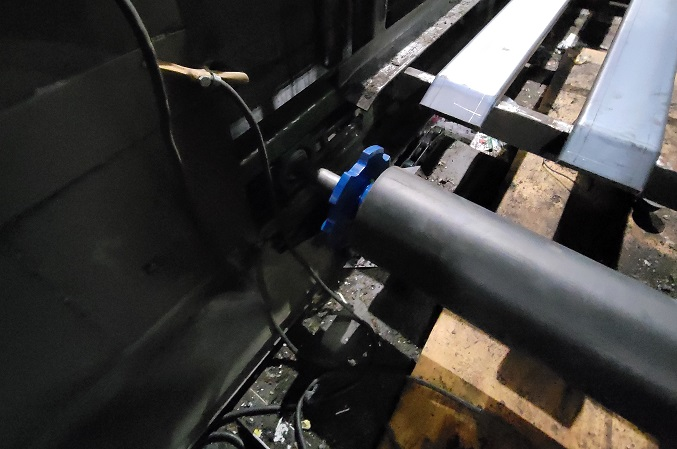

- Equipment: 72’ x 72” custom-built chain edge conveyor

- Scope: Turn-key rebuild solution

- Need: Fast-track planning, parts coordination, and a weekend install

The Problem

The aging conveyor was approaching failure. With limited documentation and no room for error, the customer needed a partner who could take ownership of the entire process.

- Aging, worn components with limited documentation

- Critical equipment with minimal downtime flexibility

- Rebuild had to occur over a two-day weekend window

- Required on-site and off-site coordination for parts and fabrication

The Solution

Lovegreen took on full project responsibility — verifying the system in the field, identifying and sourcing all needed parts, fabricating custom components, and executing the full rebuild over a single weekend.

Key responsibilities included:

- Field verification of all dimensions and components

- Developed complete parts list and sourced chain, belt, sprockets, shafts, and bearings

- Fabricated custom parts including chain guides, flights, and impact pans

- Coordinated logistics to stage parts and prepare for weekend rebuild

- Completed install with dual 12-hour shifts over two days (4 millwrights on days, 4 on nights)

- Conveyor was fully operational at end of project

Specialized Equipment Used:

- 15,000 lb forklift

- 19,000 lb forklift

- 1- and 2-ton chain falls

- Suitcase welders